Home > Pressure Die Casting Mold

Aluminum Casting Molds

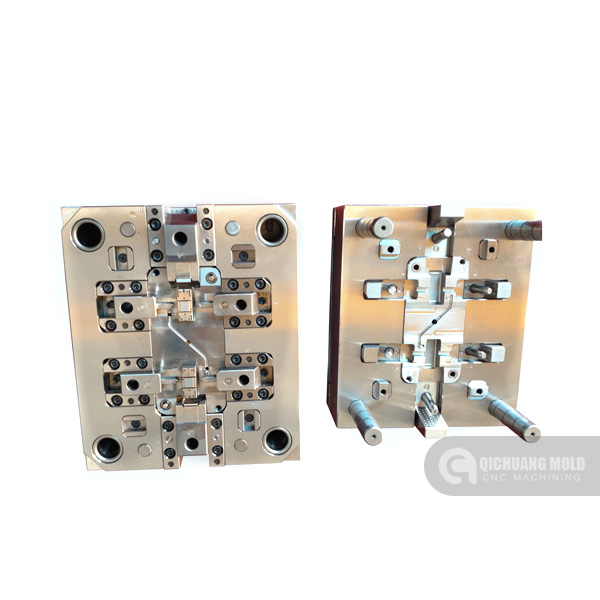

- Product description:aluminum casting molds

We offer die cast tooling and squeeze cast tooling design, engineering, and production tooling for advanced manufacturing processes for complex, high-performance products. Our die cast tooling solutions include tooling for precision aluminum and magnesium castings for complex products such as wheels, brake drums, and suspension components. Our high-speed machining and automated EDM (Electrical Discharge Machining) capabilities ensure superior die cast tooling performance providing unsurpassed castings with dimensional accuracy, tight tolerances, and smooth finishes.

Die Cast Tooling Casting Specifications

Alloys/Metals

Aluminum

Magnesium

Zinc

Castings Range:

Ounces to 300 lb. Castings

Die Cast Tooling Advantages

Wide Range of Complex Applications

Excellent Dimensional Accuracy

Close Tolerances

Smooth Cast Surfaces

Casting Tensile Strength

Reduce or Eliminate Post Machining Operations

Rapid Production Rates

Finishing:

Post finishing includes blasting, polishing, plating, painting, printing, anodizing, and precision fine machining. Pressure die casting is a method of processing aluminum into engineering shapes by molding molten metal into hardened pressure die casting molds.

About Die Casting

The die casting process forces molten aluminum, magnesium, and zinc under high pressure and control speed into the cavities of two part tooling molds—a fixer die half and an ejector die half with the impression of the casting component fabricated into the die or mold. Pressure is maintained on the mold until the hot metal solidifies and once hardened, the die is opened to remove the casting.

Our Mold Workshop:

Our Toshiba Die Casting Machine:

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva