Rapid Prototyping Manufacturing of Automotive Parts

Rapid Prototyping of Automotive Parts(Humanoid Robots, aerospace, UAV,medical equipment)

We focus on manufacturing parts prototypes for various industries, including automotive parts prototypes, robot parts prototypes, drone parts prototypes, medical equipment prototypes, and aerospace parts prototypes

In the automotive industry, any component failure or defect can lead to catastrophic consequences. Therefore, for any new component or product, it is crucial to conduct comprehensive testing and evaluation before its launch to ensure that its performance meets expectations. In this regard, prototypes have become an ideal solution for such testing operations.

QC-Mold Company has adopted rapid prototyping technology to produce high-performance physical prototypes that have been rigorously validated and tested. This technology not only ensures the quality and performance of products, but also greatly shortens the development cycle of products, thereby meeting market demand more quickly.

QC-Mold Company is committed to providing customers with first-class quality products. We deeply understand that only through strict quality control and continuous innovation can we win the trust and satisfaction of customers. Therefore, we always adhere to customer centricity, quality as our life, and innovation as our driving force, providing customers with the highest quality products and services.

Rapid Prototyping & Parts Manufacturing for Automotive Industry

QC-Mold is a company dedicated to providing professional services to the automotive industry, focusing on manufacturing automotive components and customizing rapid prototyping. By optimizing production processes and reducing costs, we can produce higher quality components at competitive prices faster. We serve well-known car companies such as BYD and Tesla. [Get instant quotes]

|

|

|

Our strong automotive component processing capabilities

Our Automotive Parts Manufacturing Process

At every stage of the manufacturing cycle, from initial prototype design to final mass production, we are committed to providing the highest quality services. QC-Mold has a variety of advanced manufacturing technologies to ensure the creation of high-quality automotive components for you.

|

CNC machining services With precision 3-axis, 4-axis, and 5-axis CNC machining centers, fast and efficient CNC machining can produce automotive parts within five days. |

|

Injection molding prototype services From prototype design to production of parts, our customized injection molded parts service ensures lower costs and faster production speed. At the same time, we also provide customers with a rich selection of materials and finishes to meet different needs and preferences. |

|

Sheet metal processing services The custom sheet metal prototype production service is committed to providing fast and cost-effective solutions for your project from small batch to mass production. We are well aware that time and cost are crucial factors in the product development process, so we focus on optimizing the production process to ensure that you can obtain high-quality products in the shortest possible time and at the lowest cost. |

|

3D printing prototype service 3D printing rapid prototyping, successfully transforming your concepts into physical objects, allowing you to test your products at a lower cost and faster time |

|

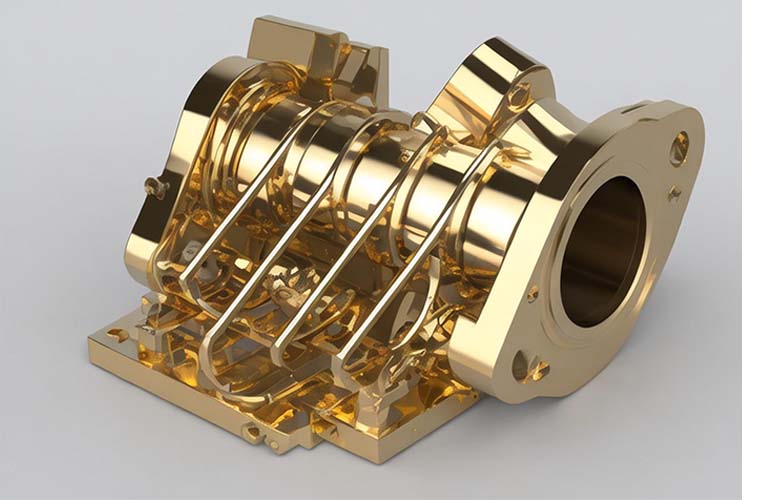

Die casting rapid prototyping service We have strict die-casting processes to ensure that all your personalized needs are fully met. Our engineering team is skilled and equipped with advanced equipment to consistently produce durable prototypes and parts. |

What are the advantages of rapid prototyping in the automotive industry

|

|

|

Reduce the cost of rapid prototyping of parts A significant advantage of rapid prototyping is its ability to quickly transform product ideas into tangible entities. In a relatively short period of time, various product designs can be created, tested, and evaluated. Once the design is finalized, it can directly enter the production phase, thus avoiding expensive costs in the future. This method not only improves efficiency, but also reduces costs, making the innovation process more efficient and feasible. |

Product iteration Rapid prototyping technology provides industry experts with an efficient and convenient method to quickly construct working models for new part designs. Compared to the strict design limitations imposed by traditional manufacturing processes, rapid prototyping not only accelerates the process of product development, but also provides greater flexibility and freedom, making product customization more refined and able to meet specific requirements. |

|

|

|

Market testing Rapid prototyping is an efficient technology that can help industry experts quickly build working models for new part design. Compared with traditional manufacturing processes, rapid prototyping has greater flexibility and freedom, as it is not constrained by the strict design limitations in traditional manufacturing processes. This enables designers to customize products to a greater extent based on specific needs and requirements, thereby creating products that better meet user needs.

|

Quality and safety assurance By adopting rapid prototyping technology, manufacturers can design and develop safer, more environmentally friendly, and lightweight parts. This process allows them to experiment and compare different design schemes, in order to select the most effective and efficient solution. In addition, due to the shorter cycle from design to delivery compared to other technologies, rapid prototyping significantly improves production efficiency.

|

QC-Mold has always been committed to providing efficient and fast prototyping and customized parts services to meet the diverse needs of the automotive industry. We focus on providing stable and reliable solutions for new product development, conducting strict quality testing to ensure that the quality of the automotive components we provide far exceeds industry standards. Meanwhile, our on-demand production model can flexibly adapt and meet your manufacturing goals.

Rapid prototyping

In the early stages of automotive product development, prototypes play a crucial role. It not only validates the design, but also provides necessary modifications for selecting appropriate materials for automotive components. At qc moldE, we provide technical support for the entire project to ensure reliable solutions for new product development and manufacturing of parts. Our goal is to exceed industry standards and meet your manufacturing requirements.

Engineering Verification and Testing (EVT)

During the engineering verification and testing phase, we can rigorously inspect the functional characteristics of the part prototype to ensure that it meets the standard requirements. QC-Mold provides 24/7 design and engineering support, and our professional team will provide you with appropriate advice and produce the highest quality products at the most reasonable price.

Design Verification and Testing (DVT)

Choose the best material from various materials to design decorative options that meet your specific design needs. Durable and high-quality coatings give parts a beautiful finish that can withstand market tests.

Mass Production (MP)

The core task of this stage is to carry out large-scale production of final use parts, with the two most critical goals being to ensure rapid delivery of parts and precise quality. Therefore, QC-Mold provides a series of quality control measures. Firstly, strict quality control is achieved through meticulous inspection to ensure that every component meets the standards. Secondly, in order to meet the optimal surface requirements, the parts are subjected to secondary processing to improve their surface quality. Finally, in order to always meet strict tolerance requirements, we adopt precision machining technology to ensure the dimensional accuracy of the parts.

Automotive component manufacturing materials

aluminium

Aluminum has become the preferred material for producing lightweight automotive components due to its excellent strength to weight ratio. This metal not only has excellent rigidity, but also has excellent corrosion resistance, ductility, and high machinability, making it widely used in automotive manufacturing.

titanium

Titanium is a metal widely used in the automotive industry, and its unique properties make it an ideal choice for many automotive components. Titanium has excellent chemical and corrosion resistance, which means it can maintain stable performance under various environmental conditions, whether in high temperature, high humidity, or corrosive environments.

steel

Steel is an indispensable metal material in modern automotive component manufacturing, known for its durability and high performance. It not only produces high-quality parts, but also has excellent corrosion resistance and lightweight characteristics, making the produced parts both beautiful and practical.

copper

Copper plays a crucial role in the automotive industry, particularly in improving comfort, efficiency, and safety. Due to its excellent electrical conductivity, high ductility and plasticity, copper is widely used in automotive electronic components.

thermoplastic

In the automotive industry, various thermoplastic materials are widely used, including high-density polyethylene (HDPE), polypropylene, acrylic acid, polycarbonate, polyphenylene sulfide (PPS) ABS and PC-ABS, etc. These thermoplastic materials are favored for their unique properties, especially their excellent impact resistance and high temperature resistance.

Liquid silicone rubber

The application of liquid silicone rubber is very extensive, among which the most common uses include manufacturing gaskets LED buttons and seals. These components play a crucial role in the normal operation of automobiles, and the excellent performance of liquid silicone rubber ensures the reliability and durability of these components.

Choosing multiple surface finish options can significantly improve the surface quality of your product. Especially in CNC turning parts, appropriate surface treatment can not only improve their appearance, but also enhance the surface hardness and roughness, improve chemical resistance and corrosion resistance, and other properties. In addition, they also help conceal any visible tool marks that may occur during the cutting process with power cutting tools. Here are some of the best surface treatment options selected for you.

Polishing treatment: Through polishing treatment, small defects and marks on the surface of CNC turning parts can be removed, making their surface smoother, thereby improving the overall aesthetics and touch.

Anodizing: Suitable for aluminum alloy materials, anodizing treatment can form a hard protective film on the surface of parts, enhance their wear and corrosion resistance, and provide a variety of color choices.

Coating treatment: By electroplating or chemical plating, a layer of metal or alloy is applied to the surface of the part, which not only improves the appearance but also enhances the conductivity, corrosion resistance, and wear resistance of the part.

Sandblasting treatment: Sandblasting treatment can form a uniform roughness on the surface of parts, enhance the adhesion of coatings, and also provide a good foundation for subsequent surface treatment.

Laser engraving: Using high-energy laser beams to carve fine patterns or text on the surface of parts not only increases product recognition, but also enhances surface wear resistance to a certain extent.

Why did you choose us to manufacture parts for rapid prototyping

Trusted by automotive engineers and designers from Fortune 500 companies, we provide customers with extremely low-cost automotive component processing solutions. We are your reliable partner in expert design of automotive components or specific parts, from rapid prototyping to customized production. To help you meet production requirements and industry standards, we provide solutions during the innovation phase.auto parts maker.Automotive parts manufacturing.Automotive parts.

|

|

|

|

|

Comprehensive Solutions |

Expertise and Experience |

Streamlined Process |

Cost-Effective and Efficient Production |

|

We offer a wide range of plastic injection molding services, all conveniently available under one roof, providing you with ultimate convenience and simplicity. Plus, with NO MOQ requirements, we’re flexible to meet your needs, whether you need a few parts or thousands. |

Our in-house team of engineers and designers boasts extensive experience and expertise in plastic injection molding. We ensure high-quality results from CAD file creation to final product completion. |

Our streamlined process focuses on clear communication, enhanced efficiency, and expedited manufacturing. We aim to make the entire process as simple and efficient as possible for our clients. |

With our advanced equipment and skilled team, we can produce thousands of identical plastic parts efficiently, reducing costs and saving time while maintaining high production rates. |

keyword:china automotive parts automobile parts manufacturers. auto parts companies.

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva