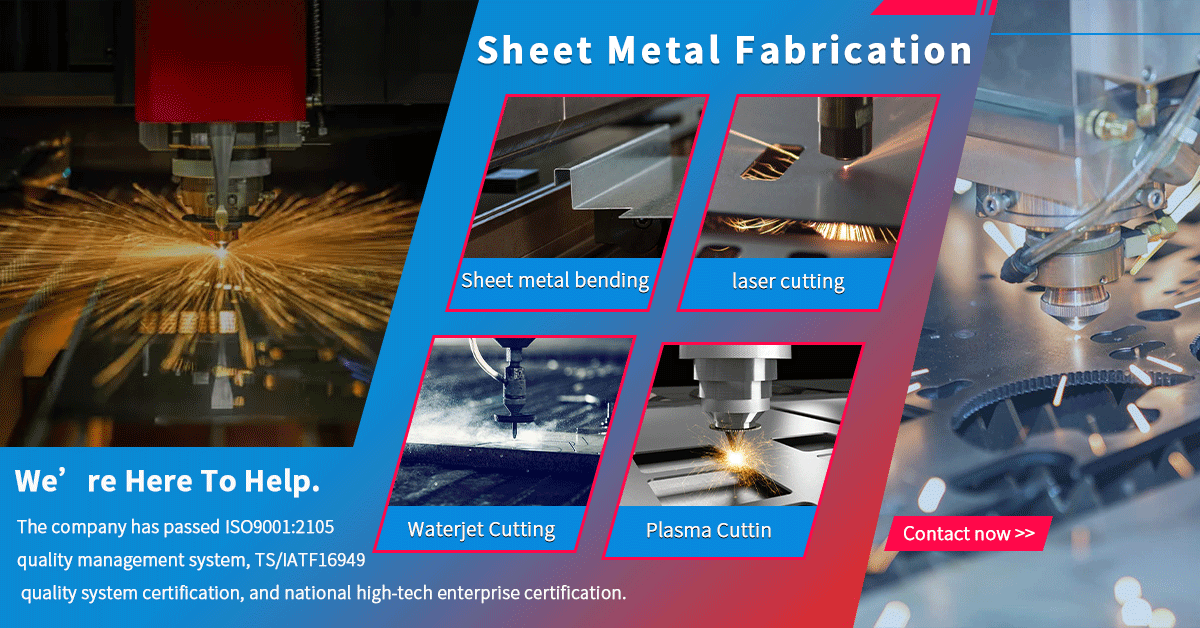

Sheet metal processing

Order sheet metal parts online

We provide metal cutting and bending services to help customers with sheet metal parts processing. The automated cutting process guarantees high precision and high quality of the finished parts. According to customer needs, all parts can be sprayed, heat treatment and other post-processing.

|

|

|

Laser cuttingConsulting quotation |

Plasma cuttingConsulting quotation |

Water jet cuttingConsulting quotation |

Get a quote in a few simple steps

Advantages of ordering sheet metal parts from qc-mold

|

|

|

|

|

Fast delivery |

High production efficiency and large scale |

Diverse choice |

Strict quality control |

|

Our mold lead time is very short: for fast tooling, prototypes can be obtained in 5-10 working days |

Can be mass produced, we can quickly produce large quantities of products for you |

Using a variety of different materials, dozens of different combinations of surface treatments, tolerances and marking are available. We also provide material certification |

We use strict internal quality control to ensure that the parts are flawless. |

Sheet metal processing product sample

Overview: What is sheet metal?

Basic knowledge of sheet metal processing

Sheet metal machining is the process of making flat metal plates (usually between 0.15mm and 10mm in thickness) into parts and structures of various shapes. The common material for this process is a metal plate. Sheet metal processing is used to make shells, bases, brackets, stamping parts, crimp and other objects. This process can also be used for decorative purposes, such as forming patterns on metal plates.

How to process sheet metal?

In sheet metal manufacturing, thin sheet metal is placed on a platform on which a laser cutter (1) draws a programmed part pattern. Depending on the geometry of the part, sheet metal punches (2) can form additional features. After the parts are deburred, they move to the bending machine (3), where the final geometry is formed. Additional secondary machining is usually used to complete sheet metal parts.

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva