Home > Die Casting

Magnesium Die Casting

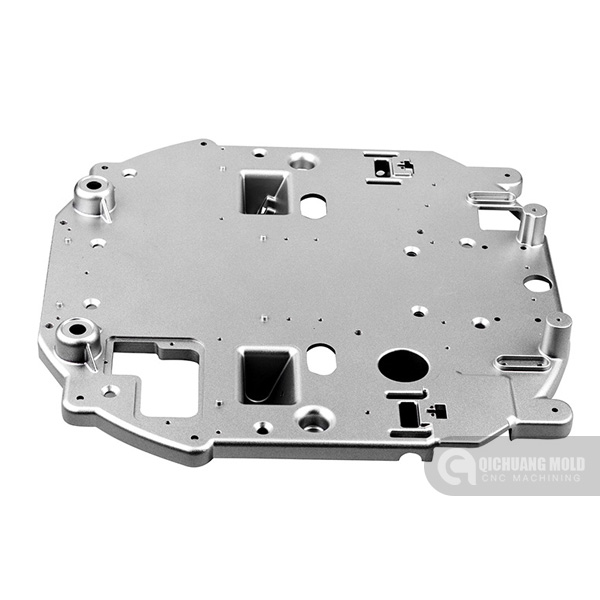

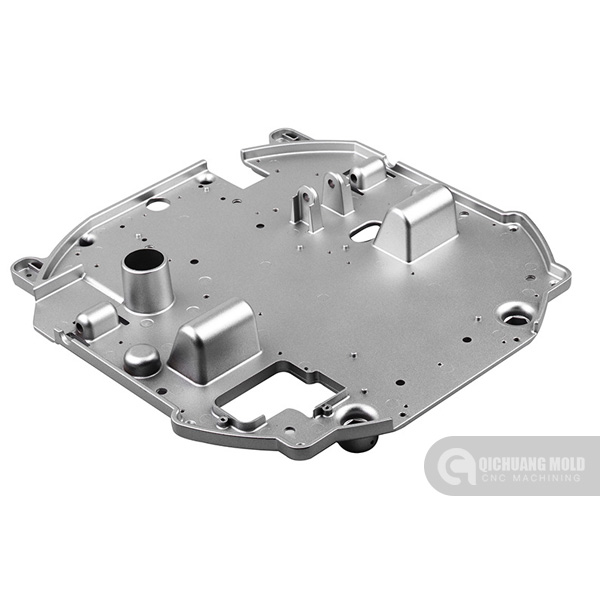

- Product description:Magnesium Die Casting

Magnesium Die Casting

Magnesium alloys have some unique solidification characteristics such as excellent fluidity and less susceptibility to hydrogen porosity, and thus, better castability over other cast metals such as aluminum and copper. Die castings made out of magnesium are very lightweight, strong and corrosion resistant. Magnesium is used when weight is a factor and a light, thin product is necessary. It is a non-ferrous metal that exhibits good soundproofing, thermal conductivity and corrosion resistance. It is easily alloyed with other metals and is considered nontoxic in its pure form.

DOING MORE FOR LESS

Our versatility enables us to quote competitively and cast competently, whether for long or short runs, large or small parts, simple or complex designs.

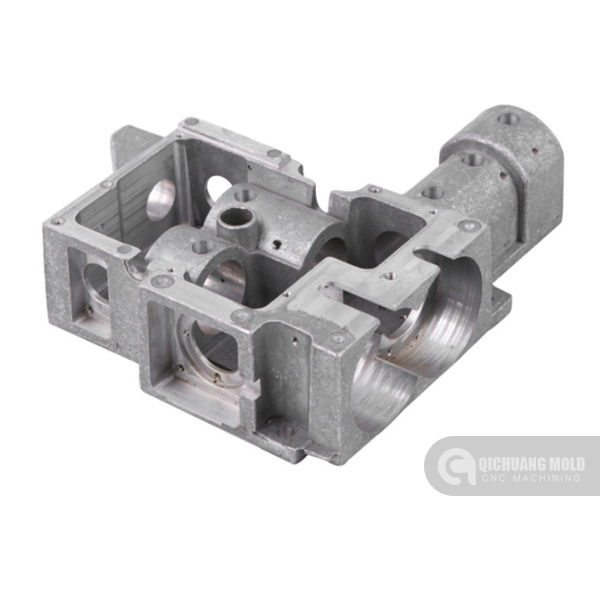

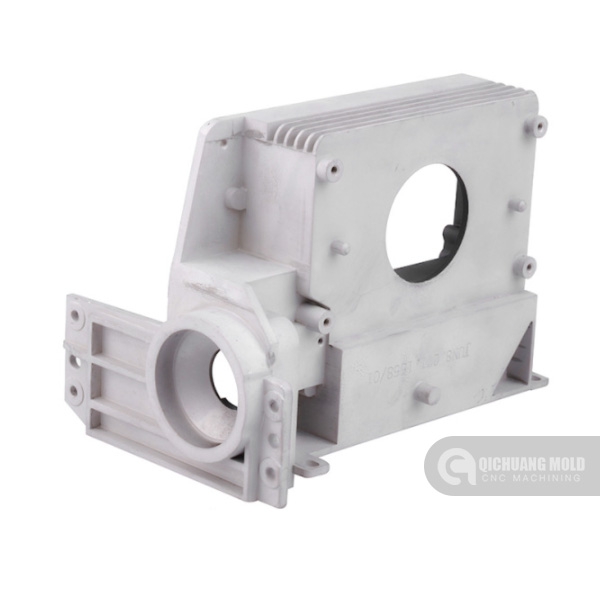

QC Mold provides superior quality custom die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.We have a wide array of die casting machines and handle many of our secondary operations in house, using our extensive machining centers. We routinely build custom machines for specific customer requirements, in order to reduce their overall costs. Our goal is to efficiently improve the functionality and manufacture ability of your designs. We offer an extensive variety of die casting, machining, and finishing operations that enable us to complete your project efficiently and economically.

Die Casting Material

The four most commonly used die casting alloys are Aluminum, Magnesium, Copper, and Zinc.

Aluminum die cast alloys: A380,,383 (ADC12), B390, A413, A360 etc.

Zin alloys including, Zamak 2, Zamak 3, Zamak 5, Zamak 7, ZA 8, ZA 27 - Zinc Aluminum, EZAC ,etc.

Magnesium die cast alloy: AZ91D, AZ91HP, AM60B etc.

Copper alloys like Yellow brass, manganese bronzes, silicon brass, alloys like C85800, C86200, C86500, C87800, and special die casting alloys like C99750 and C99700.

More special material, please feel free contact our professional engineers.

Advantages of Magnesium Die Casting● Outstanding Dimensional Control

● Ultra-Thin Wall Design Options

● Excellent Vibration Dampening and Shock Absorption

● EMI/RFI Shielding

● Long Tooling Life to Lower Total Production Cost

● Abundant Finishing Options

● Withstands Higher Operating Temperatures

● Recyclable

●Good Environmental Corrosion Resistance

● Very Good Stiffness-to-Weight Ratio

● Highest Strength-to-Weight Ratio of Die Cast Alloys

Finishing

Post finishing includes blasting, polishing, plating, painting, printing, anodizing, and precision fine machining. Pressure die casting is a method of processing aluminum into engineering shapes by molding molten metal into hardened pressure die casting molds.

|

Get Your Die Casting Project Started Today With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements. Contact us today for a free quote! |

|

|

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva