Injection mold processing services

Shaping quality and Efficiency: The power of the injection molding process

Injection molding is one of the most cost-effective ways to manufacture plastic parts in large quantities, ensuring consistent quality regardless of the yield. qc-mold offers a wide selection of rigid plastics and resins to meet the requirements of structural and visual characteristics. In addition to materials, injection-molded parts can also use custom surface treatment, polishing or surface texturing processes. qc-mold provides high precision tool manufacturing and injection molding services.

|

QC-MOLD is a world-class advanced injection molding service provider. We provide a complete manufacturing solution that covers all aspects of material identification, tool manufacturing, part manufacturing, precision machining, and final inspection. Our international manufacturing expert team is committed to providing you with the highest level of professional support for injection molding services of any scale or complexity. We provide three-layer injection molding services to ensure that you accurately obtain the most suitable solution for your expected quantity, production time, and budget. |

|

What Is Injection Molding?

At a certain temperature, the heated and melted resin raw material is injected into the mold cavity under high pressure, cooled and solidified to form a molded product.

Injection molding process type

We offer various molding and processing methods, such as plastic injection molding, liquid silicone rubber molding, encapsulation molding, and insert molding. Combining our advanced production capacity and over 20 years of team experience, we can handle all types of metal, plastic, and silicone material molding projects, regardless of the scale and difficulty of the project.

|

Qc-mold offers a full range of services:

Our services include not only injection molding but also subsequent processing steps such as cutting, grinding and painting to ensure that each component meets the highest standards. We use a variety of materials including polycarbonate, nylon and a variety of special synthetic blends to meet the needs of different applications.

|

Advantages of injection molding products

|

|

|

|

High production efficiency, able to quickly produce a large number of parts |

Capable of producing parts with complex shapes |

For mass production, it has excellent cost effectiveness |

Hardness table of injection molding die:

|

Formwork |

Minimum hardness(BHN) |

Instructions |

|

Heat-treated stainless steel |

280 |

Support fast cycle, production speed is fast |

|

Mild steel, aluminum or alloy |

>165 |

Suitable for parts with limited production, especially those using non-abrasive materials |

|

Epoxy resin, plastic

|

>165 |

Often used for prototyping |

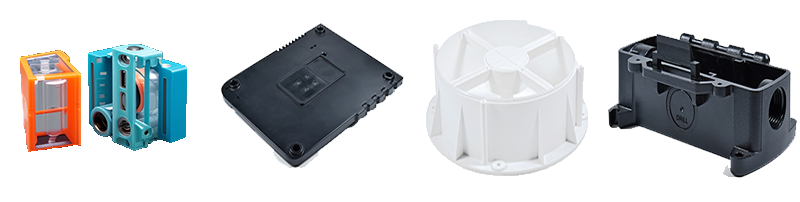

Injection molding products column

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva