Home > Manufacturing

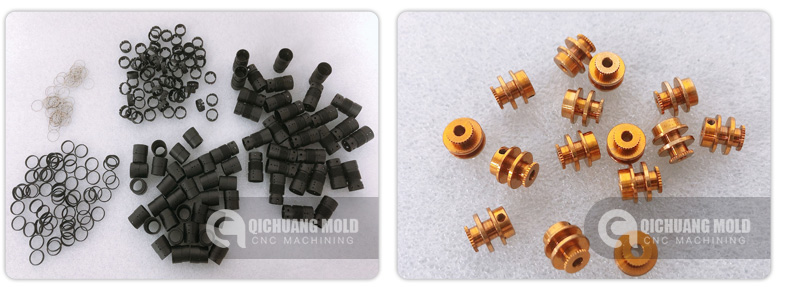

Swiss Machining Parts

- Product description:Swiss Machining Parts

About Swiss Machining

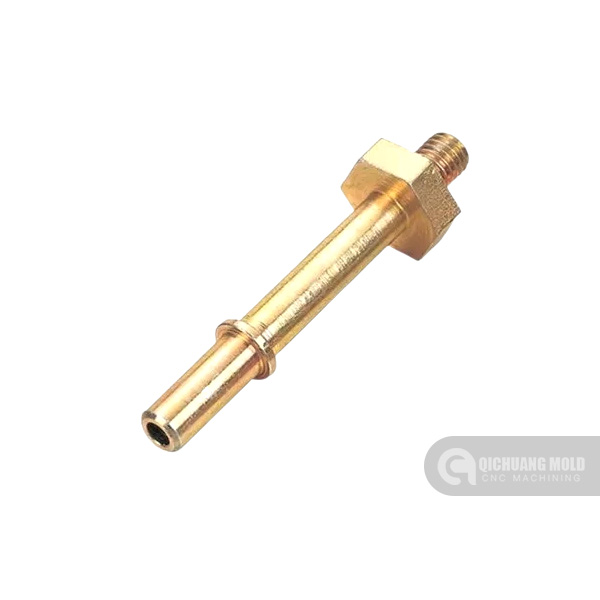

A Swiss-style lathe is a turning machine that feeds stock through a guide bushing. A tool cuts the stock near the bushing, which is the support point, regardless of the length of the workpiece. This makes Swiss machining a good choice for turning long, slender parts.Swiss machines are a fine selection for making parts with length-to-diameter ratios greater than 3-1, as well as deep, small-diameter holes. Swiss-made parts are generally under 38 mm (1.5") in diameter.Another limitation on the size of Swiss parts is the size of the machines, which are usually small and compact. Therefore, Swiss machining would not be suitable for parts more than 203 mm (8") long.

Capabilities

QC MOLD offers a complete line of CNC Swiss machining centers. we added CNC-Swiss type capabilities to its impressive list of manufacturing processes with the addition of 5-axis CNC Swiss machines that contain live tooling. This gives us a full range of machining processes for the production of precision parts without expensive secondary operations. We are now able to manufacture complex parts with ultra high-speed flexibility.Your company deserves to take advantage of the high performance and accuracy that Swiss lathe machine bring to factory operations.

From small runs of a few hundred pieces up to hundreds of thousands, Swiss CNC machining allows designers to manufacture complex components on one machine. High-volume production runs with this machining can cover numerous processes, including, milling, threading, drilling, boring, turning, and other custom requirements. One machine can perform several operations at once in a shorter period of time while offering designers more control in the production of complex parts.

Machining Materials

We work with steels, aluminum, brass, copper, iron, and titanium materials utilizing Swiss-style machining operations. We can also perform these operations with polymers such as ABS, Acetal, Fiberglass, and Nylon.Our team has produced connectors, fasteners, fittings, and shafts in prototype, low volume, or high volume batches. While we typically quote on a job by job basis, time may vary depending on the project complexity and timeframe requested.

| ✔ Aluminum | ✔ Stainless steel |

| ✔ Brass | ✔ Copper |

| ✔ Plastic | ✔ Carbon steel (all grades and alloys) |

| ✔ Nickel | ✔ Chrome alloys |

| ✔ Tube | ✔ Pipe |

Finishing Services

Our engineers are experts in achieving the perfect finish for your product. With painting, vapor polishing, sanding, anodizing and many other services to choose from, you can create the exact look you want.Anodizing, Painting, Pad Printing, Color Matching, Sanding and Polishing, Vapor Polishing, Blasting

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva