Home >

Sla 3D Printing

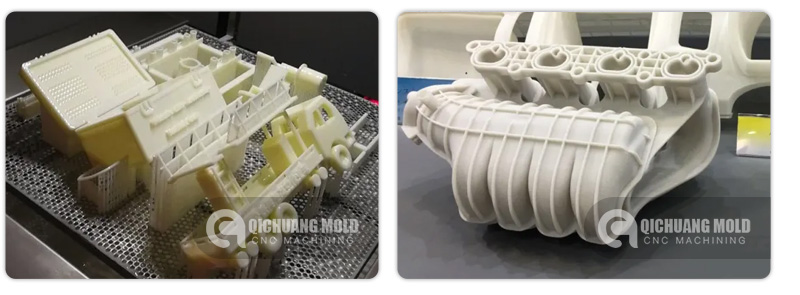

- Product description:Sla 3D Printing

Stereolithography (SLA) is an additive manufacturing process that builds models one layer at a time. With a UV light trailing the resin as it is printed, prototypes are cured (hardened) immediately after printing. CAD models provide data to the system, which traces each horizontal layer across the surface. After each horizontal layer is laid, the print tray lowers in the z-axis (height). The final step in the SLA process involves a final curation in a UV oven.

QC Mold SLA rapid prototyping services is a cost effective way to accelerate your product

development and decrease your time-to market. Outsourcing for services can save precious time if you are on a tight deadline. Employing QC Mold as your SLA service partner when your system is down, while CAD designers and product engineers could focus on the details necessary to produce high quality results.

SLA Process

Stereolithography (SLA) is an additive fabrication process utilizing a vat of liquid UV-curable photopolymer "resin" and a UV laser to build parts a layer at a time. On each layer, the laser beam traces a part cross-section pattern on the surface of the liquid resin.

SLA Benefits

Extremely Strong, Durable Models

Thin Walls

Many Finishing Options Available

Many High Caliber Materials to Choose From

One of the quickest forms of rapid prototyping

Accurate and robust parts

For instant quote please send your 3D drawings to info@qc-mold.com we will get back to you within 12 hours

Our SLA 3D printer:

Categories

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva