Home > Plastic Injection parts

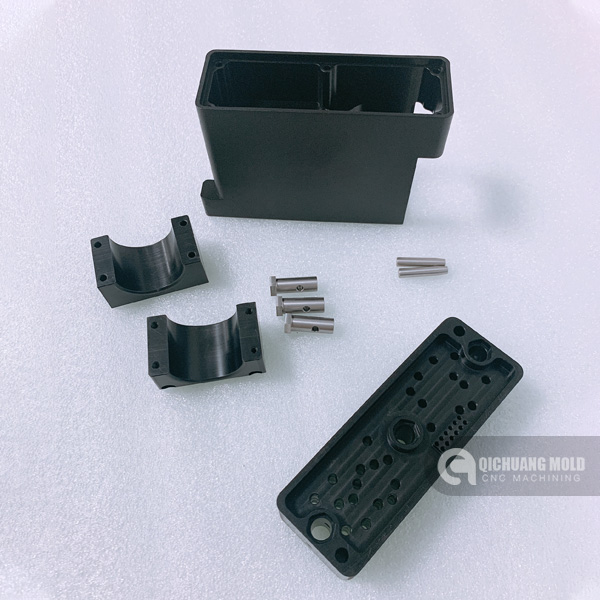

POM Prototype Machining

- Material: POM

- Process: CNC Turning and Millling

- Surface Treatment:According to your request

- 【Service】: CNC Machining Metal, CNC Machining Plastic. Injection Molding Service.

- Product description:POM CNC Machining,POM Parts Manufacturer, POM Injection Molding Manufacturer.Send You 3D Drawing To US ,Get A Fast Free Quote!

POM Prototype Machining

Polyoxymethylene (POM) is a thermoplastic material also known as acetal. It is one material that thermoplastic crystalline polymer. It is called"super steel"or "sai steel". POM is supplied in a granulated form and, with heat and pressure, can be molded into a desired shape. POM can be injection molded as well as rotational and blow molded. It can also be extruded into lengths of rectangular or round bars which can be used for machining.

Advantage of POM material CNC Machining parts:

●High mechanical strength and rigidity;

●Highest fatigue strength;

●Environmental resistance and organic solvability strong

●Widely used temperature range (- 40 ℃ ~ 120 ℃)

●Good electrical properties& insulation

●Good lubrication and abrasion

●Good resilience

●Dimensional stability

ApplicationsAnd for now, the cost of POM which is less than the others engineering plastic, and is replacing some of traditionally metal materials to machining the precision conpoments. Such as: Aluminum, Brass, Steel and Zinc etc. Since its advent, POM has been widely used in electronic electrical, mechanical, instrument, daily light industry, automobile, building materials, agriculture and so on. In many new areas, such as medical technology and sports equipment, POM has also shown better growth.

POM is an engineering material used in parts that require precision. Applications for POM include high performance components such as gear and fasteners (screws, nuts, washers, spacers, etc.). It is also used in other applications such as ski bindings, yoyos, electronic cigarettes, watch bracelets, zippers, insulin pens, and metered dose inhalers. It is used in musical instruments for picks and instrument mouthpieces, in the food industry in applications like milk pumps and coffee spigots, and also as a solvent for perfumes and as a synthetic flavoring ingredient.

The Challenges Of Machining POM

The POM is an elastic material which is very resilient. When cutting, the parts that are exposed to the tool will be deformed by the elasticity of the material, when the tool is gone, the area of the cutting will be caused some deformation automatically.How to effectively control the size of POM CNC Machining parts and avoiding the deformation or reduce deformation. As one professional Precision CNC Machining manufacturer, Creating way will get you the best choice and proposals on this.

From Concept to Production

We can machine virtually any engineering material, including plastics, metals and more.Whether you‘re a large corporation or a small business, we will work in a collaborative manner with you to ensure high quality.Taking your concept and turning it into reality,upload your drawings, start your free project review!

CNC Machining Materials

Metal : Kovar, Steel, aluminum, stainless steel, brass, copper, titanium etc.

Plastic :Acrylic \ Liquid crystal polymer \ Long-fiber reinforced plastics \ Noryl (PPO and PS) \ Polysulfone, PC, PET, PE, PPS, PP, PS, PU, PBT, PEI, Peek , PTE, PVC etc.

Contact us to know more about materials

CNC Machining Service

At QC Mold, we use advanced equipment to offer you a variety of CNC machining services including milling, turning, EDM and wire EDM, surface grinding and much more. Using our imported 3, 4 and 5-axis CNC machining centers, our skilled machinists can make turned and milled parts using a wide range of plastic and metal materials.

Whether you require a one off model for fit and function, a small batch run for marketing and testing or low volume production QiChuang has the solution for you.

CNC Milling

CNC milling is used to apply a machined surface finish on plastic or metal or for creating complex 3D shapes.

CNC Turning

Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to low-volume production.

EDM / Wire EDM And Surface Grinding

EDM (electrical discharge machining) is a method for cutting pockets, holes, and other shapes into hardened steel, as well as imparting a surface texture to the internal cavities of mold tools. A sacrificial electrode in an electrolyte bath discharges a high-powered electric spark to erode very hard materials that would be difficult or impossible to do with any other method. Square pocket holes are often created with this method.

With wire EDM, a copper wire is continuously fed between two spools. When electrically charged, it’s able to cut through hardened tool steels quickly and accurately.

At QICHUANG, we also offer surface grinding services. When surface grinding the work piece is held stationary on a horizontal plate. The surface grinding wheel is computer controlled to abrade the work piece to a precise depth.

Finishing Services

Our engineers are experts in achieving the perfect finish for your product. With painting, vapor polishing, sanding, anodizing and many other services to choose from, you can create the exact look you want.

Anodizing, Painting, Pad Printing, Color Matching, Sanding and Polishing, Vapor Polishing, BlastingFor instant quote please send your 3D drawings to info@qc-mold.com we will get back to you within 12 hours.

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva