Home > Die Casting Parts

Die-Casting Parts

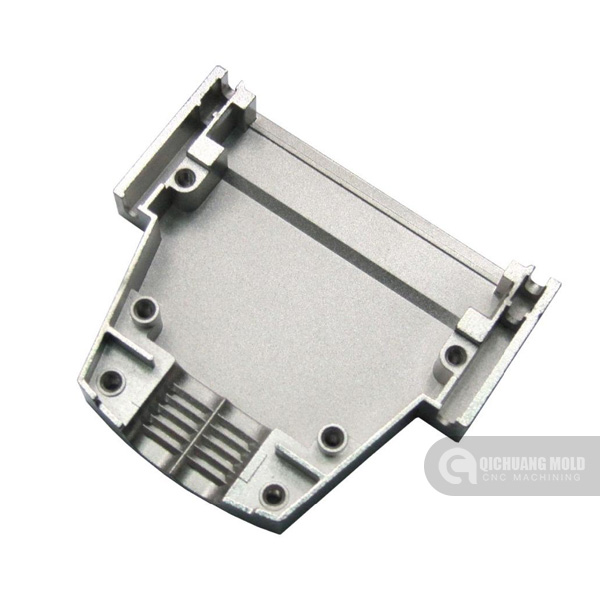

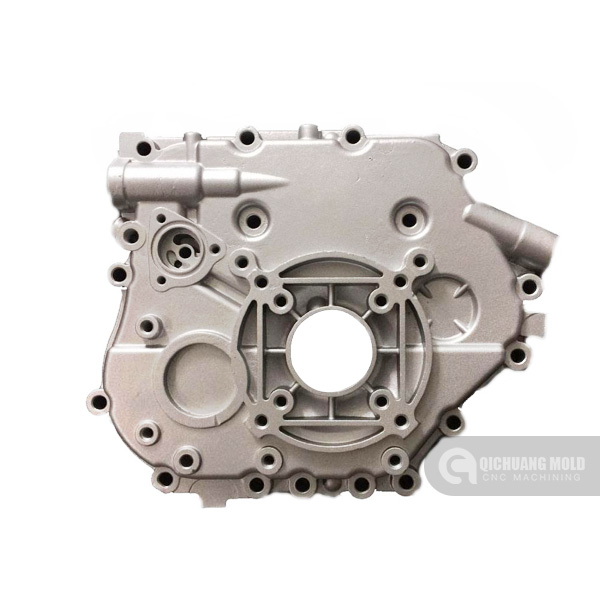

- Product description:Die-Casting Parts

Similar to an injection mold, we use certified machines and pressure casting dies to form molten metal into your designs.

Our pressure die casting process is effective and very reliable. This method can actually end up saving your money. The majority of our castings are made from zinc, copper, aluminum, magnesium, led, pewter or other tin based alloys.

Because of our flexibility, we’re able to accommodate any need you may have – from small batches of 50 to up to 1000 pieces.

Benefits

Suited for larger production runs, since die casting mold tools can be more expensive and difficult to make, price for parts produced is lower.

Surface finish and dimensional stability are excellent

Complex geometries can be made that require little or no post-machining

It is great for medium to larger sized parts that would be slower and more expensive to machine

Material

Aluminum Die Casting

Used to produce light but strong parts.

Zinc Die Casting

Zinc is used to produce ductile plated parts.

Magnesium Die Casting

Recommended in producing light parts that require a excellent strength but keeping the weight in check.

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva