Home > Product

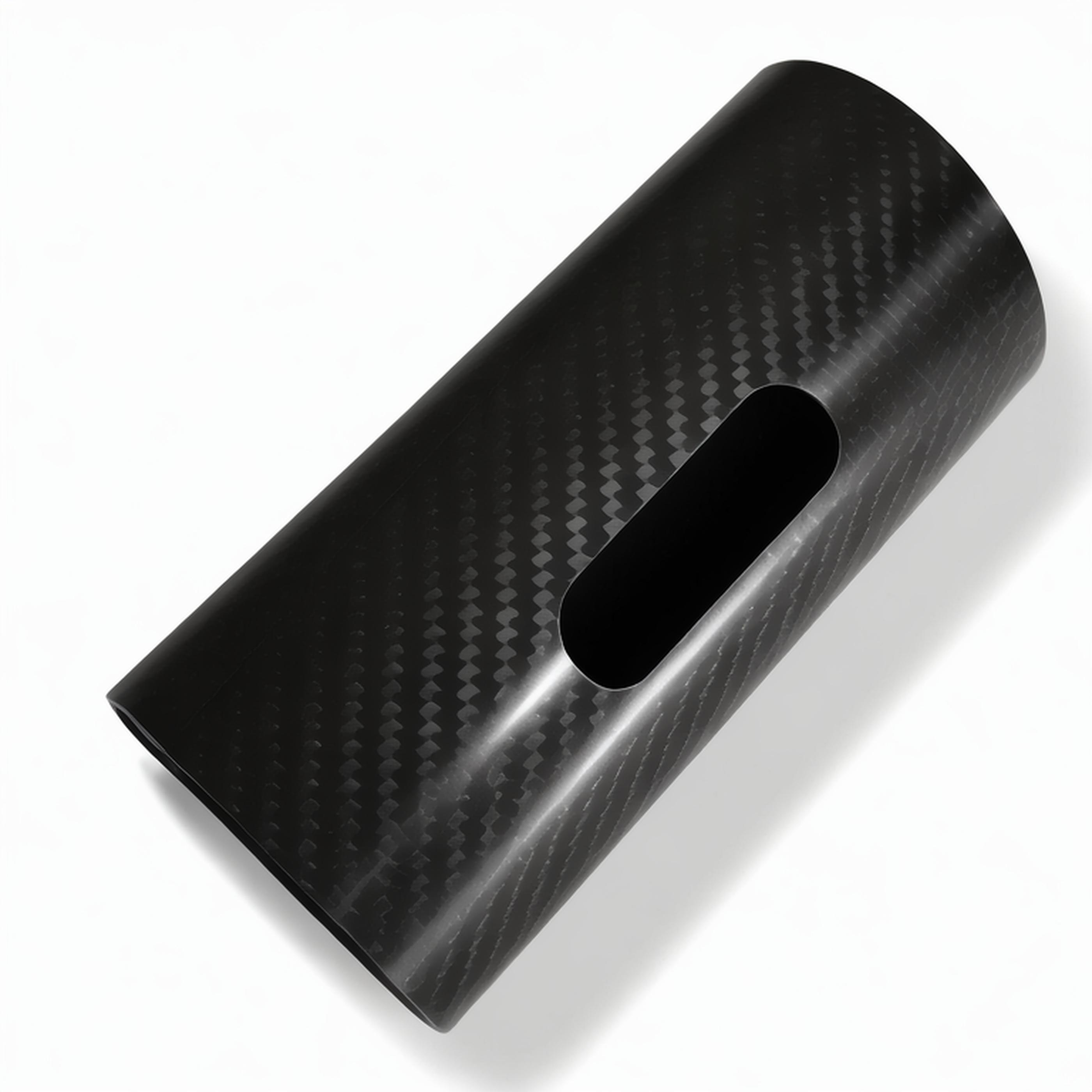

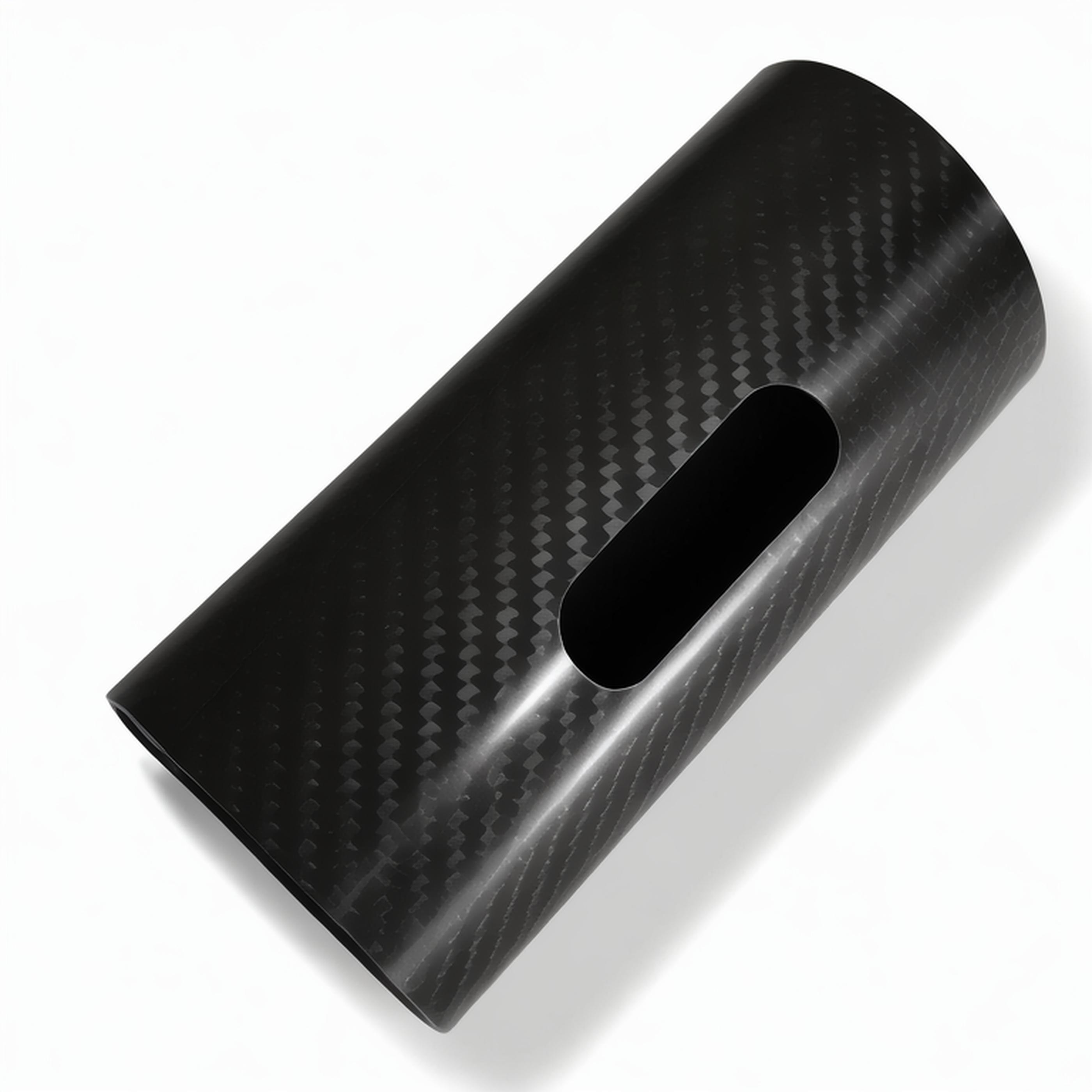

Custom carbon fiber parts

- Custom carbon fiber parts

- carbon fiber

- Rapid Prototype

- Customized parts

- Product description:Craft your project with the strength and lightweight efficiency of our custom carbon fiber parts. As a leading manufacturer of high-performance materials, we specialize in producing carbon fiber compo

Carbon fiber has become a critical material in various industries due to its unique combination of strength, light weight, and versatility. Customized machining of carbon fiber parts is essential for industries that demand high performance, durability, and bespoke solutions tailored to specific applications. In this article, we explore the benefits, applications, and capabilities of customized carbon fiber machining, highlighting how it can drive your business forward.

Why Choose Carbon Fiber?

Superior Strength-to-Weight Ratio

Carbon fiber composites are known for their exceptional strength and lightweight properties. They are up to five times stronger than steel and yet much lighter than both steel and aluminum (RpProto) (Nitpro Composites). This makes carbon fiber the material of choice for industries where weight reduction is crucial without compromising on strength, such as aerospace, automotive, and sports equipment.

Durability and Corrosion Resistance

Carbon fiber is highly resistant to corrosion and can withstand extreme environmental conditions, including high temperatures and exposure to chemicals (Nitpro Composites). This durability ensures long-lasting performance in harsh environments, making it ideal for marine, medical, and military applications (ESE Industries) (Real Carbon).

Versatility and Customization

The flexibility of carbon fiber allows for a wide range of customization options. Whether it's complex shapes, intricate designs, or specific performance requirements, carbon fiber can be tailored to meet diverse needs through advanced machining processes (ESE Industries) (RpProto).

Applications of Custom Carbon Fiber Parts

Aerospace and Automotive

In the aerospace and automotive industries, weight reduction is directly linked to fuel efficiency and performance. Custom carbon fiber parts, such as structural components, body panels, and aerodynamic elements, contribute to significant weight savings while maintaining structural integrity (RpProto).

Medical and Industrial Equipment

Carbon fiber's strength and resistance to wear make it suitable for medical devices and industrial machinery. It is used to manufacture prosthetic limbs, surgical instruments, and high-precision industrial tools (Real Carbon).

Consumer Electronics and Sports Equipment

From lightweight bicycle frames to high-performance drones and musical instruments, carbon fiber's lightweight and robust characteristics are leveraged in various consumer products to enhance usability and performance (Real Carbon).

Customized Machining Capabilities

Precision Cutting and Shaping

Modern CNC machining techniques enable precise cutting and shaping of carbon fiber, accommodating complex geometries and tight tolerances. This precision is crucial for applications requiring exact specifications and high-quality finishes (Nitpro Composites).

Mold Fabrication and Prototyping

Customized mold fabrication allows for the production of complex carbon fiber parts tailored to specific design requirements. This process is essential for prototyping and validating new designs, ensuring they meet functional and performance standards before full-scale production (ESE Industries).

Surface Finishing and Treatment

Advanced finishing techniques, such as high gloss, matte, and satin finishes, provide carbon fiber parts with the desired aesthetic and functional properties. These finishes enhance the appearance and durability of the final product, catering to both functional and cosmetic needs (Nitpro Composites).

Why Partner with Us for Custom Carbon Fiber Machining?

At [qc-mold], we specialize in the customized machining of carbon fiber parts, offering end-to-end solutions from concept to completion. Our state-of-the-art facilities and experienced team ensure that we deliver high-quality, precise, and cost-effective carbon fiber solutions tailored to your specific needs.

Expertise and Innovation

With years of experience in carbon fiber machining, we bring expertise and innovative approaches to every project. Our commitment to quality and precision ensures that our carbon fiber parts meet the highest industry standards.

Flexible and Scalable Solutions

Whether you need a low-volume prototype or a large-scale production run, our flexible manufacturing capabilities can accommodate projects of all sizes. We provide tailored solutions that adapt to your unique requirements and timelines.

Customer-Centric Approach

We prioritize our clients' needs, working closely with you to understand your specific requirements and deliver solutions that exceed expectations. Our customer-centric approach ensures a seamless and satisfying experience from start to finish.

Get Started with Your Custom Carbon Fiber Project

Are you ready to take your project to the next level with custom carbon fiber parts? Contact us today for a consultation and quote. Let us help you transform your ideas into high-performance, durable, and lightweight solutions that drive your business forward.

CNC Machining Center

Categories

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva