News

What is rapid prototyping of automotive parts?How are Car Parts Manufactured?

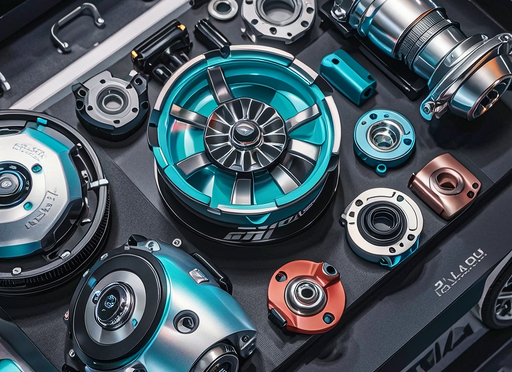

Rapid Prototyping of Automotive Parts: car parts,auto parts

In the dynamic realm of automotive manufacturing, rapid prototyping has emerged as a pivotal process, driving innovation and efficiency throughout the industry. This article explores the definition, principles, applications, pricing, influencing factors, product features, raw materials, quality aspects, innovation points, unique advantages, parameters, successful cases, and user evaluations of rapid prototyping in automotive parts manufacturing.

Definition, Principles, and Applications

Definition: Rapid prototyping involves the quick creation of physical parts using additive manufacturing technologies, such as 3D printing, to test and validate designs before full-scale production. It accelerates the product development cycle, reduces time-to-market, and enhances design flexibility.

Principles: The core principles of rapid prototyping include rapid iteration, cost-effectiveness in low-volume production, and the ability to incorporate design changes swiftly based on testing and feedback.

Applications: Rapid prototyping finds applications across various automotive sectors, including concept car development, functional testing of parts like engine components and interior fittings, and manufacturing customized or niche vehicle parts.

Pricing and Influencing Factors

Pricing: The cost of automotive parts prototyping varies based on factors such as complexity, size, material used, and desired finish. Initial setup costs for prototyping equipment and subsequent material costs contribute significantly to pricing.

Influencing Factors: Key factors influencing pricing include technology choice (e.g., selective laser sintering vs. fused deposition modeling), material selection (e.g., metals, polymers), part complexity (e.g., intricate geometries vs. simple shapes), and post-processing requirements (e.g., surface finishing, painting).

Product Features, Models, Colors, and Advantages

Product Features: Rapid prototyping allows for the creation of complex geometries, lightweight structures, and parts with integrated functionalities like internal channels or lattice structures.

Models and Colors: Various models (e.g., functional prototypes, appearance prototypes) can be produced in a range of colors using colored filaments or post-processing techniques like painting and dyeing.

Advantages: Advantages include accelerated time-to-market, reduced development costs, enhanced design flexibility, improved product quality through iterative testing, and the ability to produce customized or on-demand parts.

Introduction to Raw Materials and Quality

Raw Materials: Common raw materials for automotive prototyping include engineering plastics (e.g., ABS, nylon), thermoplastics (e.g., PLA, PETG), and metal alloys (e.g., aluminum, stainless steel) suitable for specific performance requirements (e.g., heat resistance, strength).

Quality: Quality control measures ensure dimensional accuracy, material strength, surface finish, and part integrity. Advanced scanning and inspection technologies verify prototypes against design specifications.

Innovation Points and Unique Advantages

Innovation Points: Rapid prototyping fosters innovation by enabling rapid iteration, facilitating design optimization, supporting agile manufacturing practices, and encouraging collaborative design processes.

Unique Advantages: Unique advantages include the ability to produce complex geometries not feasible with traditional manufacturing methods, enabling rapid customization, reducing tooling costs, and supporting sustainable manufacturing practices through reduced material wastage.

Parameter Introduction, Successful Cases, and User Evaluation

Parameter Introduction: Key parameters in automotive prototyping include layer height, infill density (for 3D printing), build volume, resolution, material properties (e.g., tensile strength, flexibility), and surface finish.

Successful Cases: Examples of successful applications include prototyping of electric vehicle components, lightweight structures for improved fuel efficiency, and ergonomic interior components enhancing user experience.

User Evaluation: User evaluations focus on prototype functionality, durability, fitment, aesthetic appeal, and overall performance against design criteria. Feedback informs iterative design improvements.

Conclusion

Rapid prototyping of automotive parts continues to redefine industry standards by accelerating innovation cycles, enhancing design flexibility, and optimizing manufacturing efficiency. As technologies advance and materials evolve, the future promises even greater capabilities in transforming automotive design and production processes.

In essence, the integration of rapid prototyping represents a pivotal advancement, empowering automotive manufacturers to achieve unprecedented levels of creativity, efficiency, and performance in delivering cutting-edge vehicles to the market.

Categories

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva